Fabrication and assembly

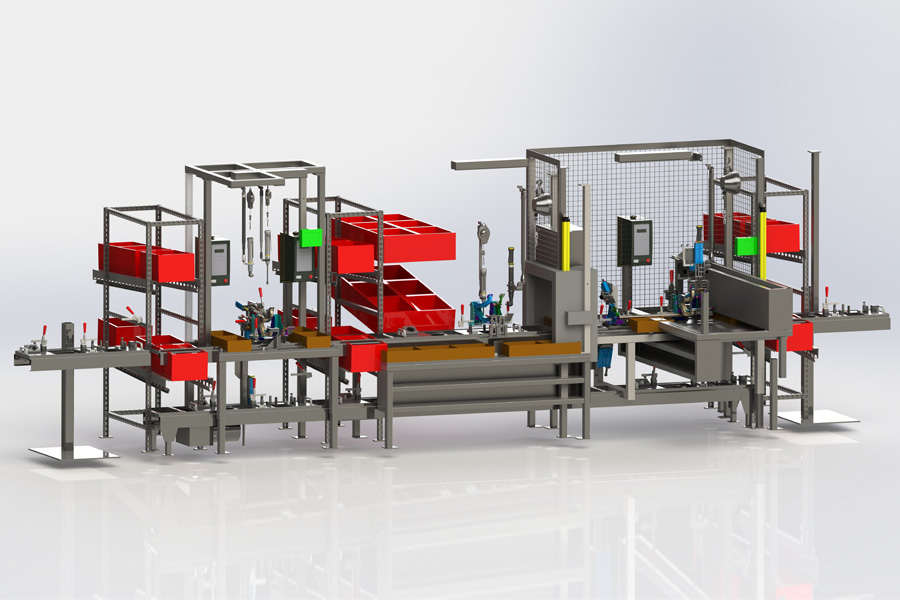

Automating processes, faster speeds, less hassle: ATI helps its clients at every step in improving their production lines, by offering reliable, competitive, innovative solutions.

ATI offers turnkey solutions for integrating capacity equipment (machinery) and special equipment (dedicated tools) from the time when needs are defined to when the equipment is installed and the staff is being trained.

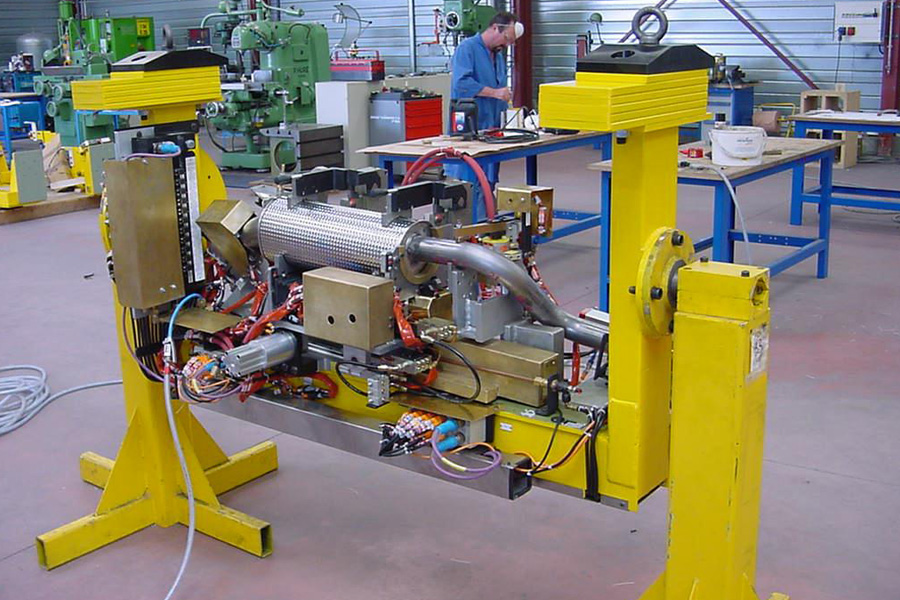

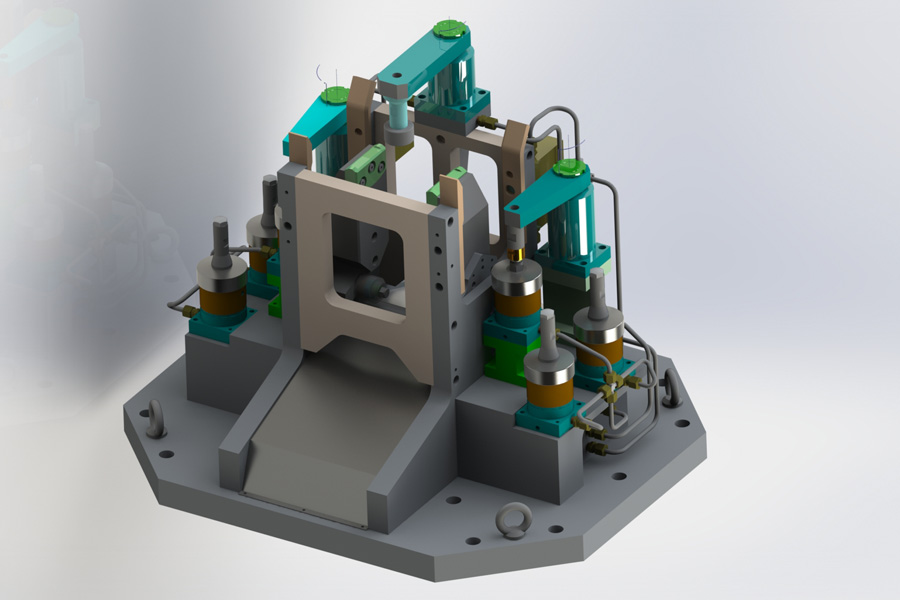

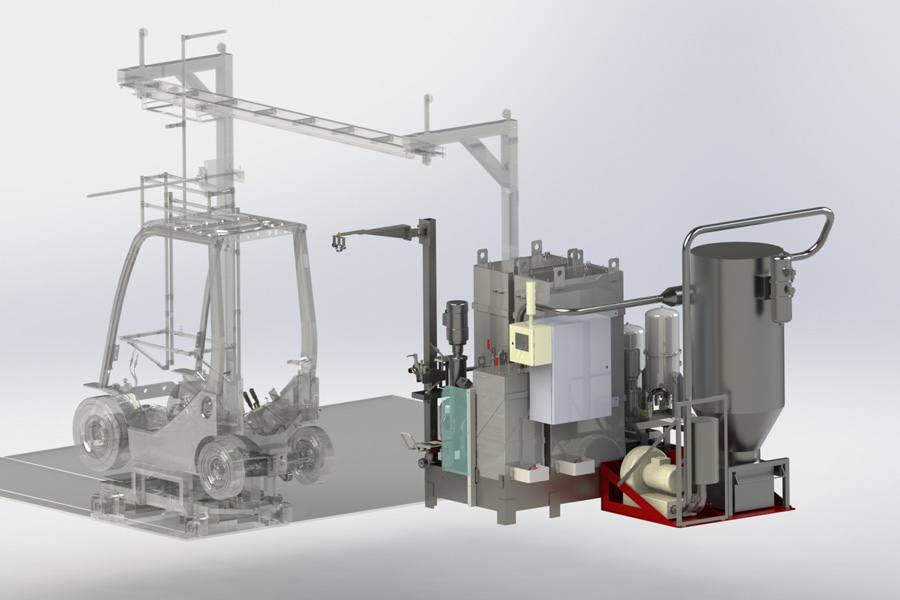

Welding

ATI Solutions, which manufactures welding equipment, designs welding tools and machines that include several technologies :

- Resistance welding: This process does not need any outside filler: A strong electrical current heats the material, then pressure joins it together. Different types of resistance welding are possible: Spot, projection or rotary welding.

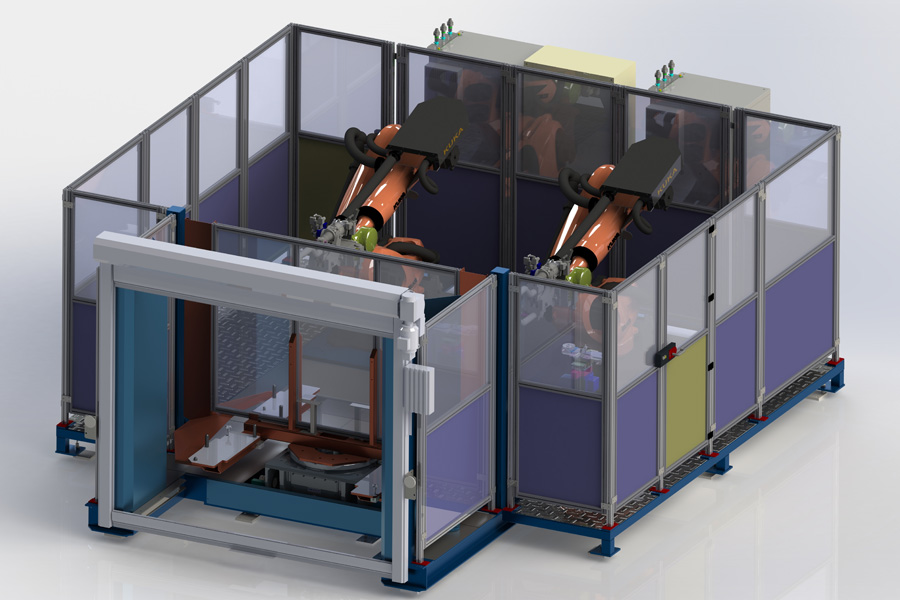

- MAG (Metal Active Gas) welding: Carried out in an active gas mixture, which helps improve the weld's quality and protects the puddle from oxidization from ambient air. We offer, among other things, MAG tools for manual welding or for robotized cell.

- Laser welding: This type of tool enables fast, accurate welding. The heat source is powerful, while being focused on a small area, which limits the alteration of the materials to be welded.

- Induction welding: This technology dedicated to certain materials is energy-efficient and makes it possible to lower the surface area of the heat-treated part.

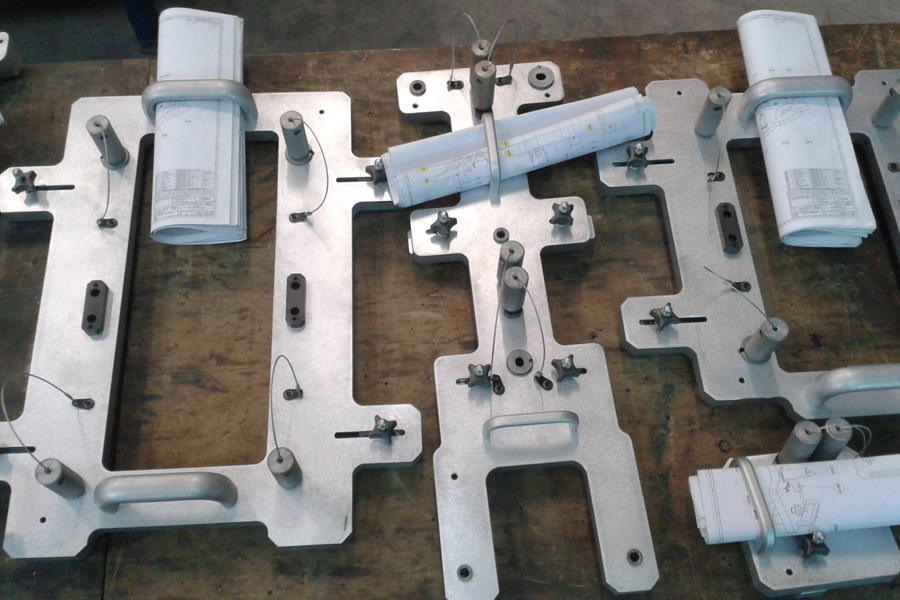

We design your project together, and track it from A to Z :

- We offer a balanced solution of capacity and special equipment, taking into account production changes.

- We choose the best capacity solution: Special machines, robotized cells, etc.

- We perform the sizing and select the right robotic equipment.

- We determine what your needs are and offer you a suitable tool for your sector of business and your constraints.

- We design the tools, make them, and tune them.

- Our teams install the equipment and train you in how to use it.

- We also perform post-sales follow-up on all of our machines.

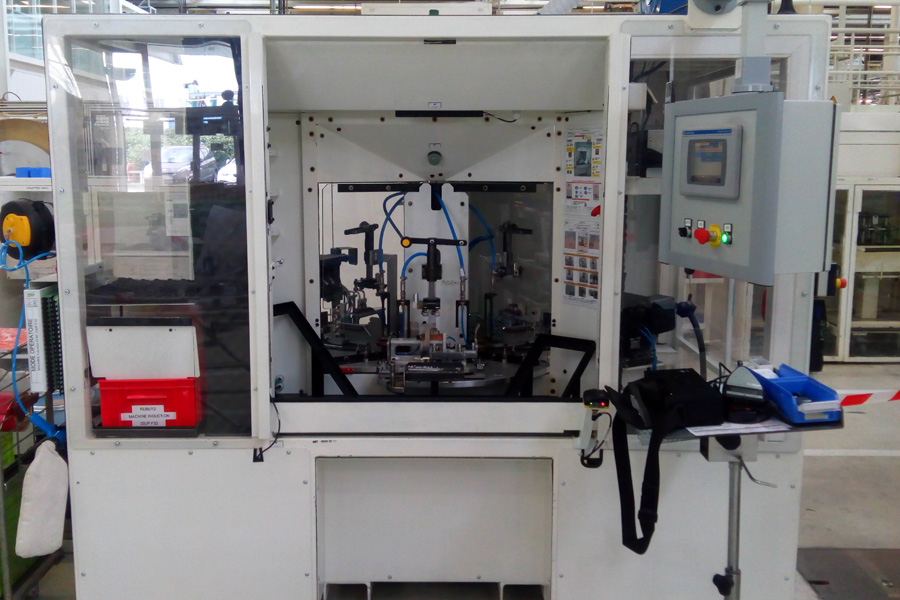

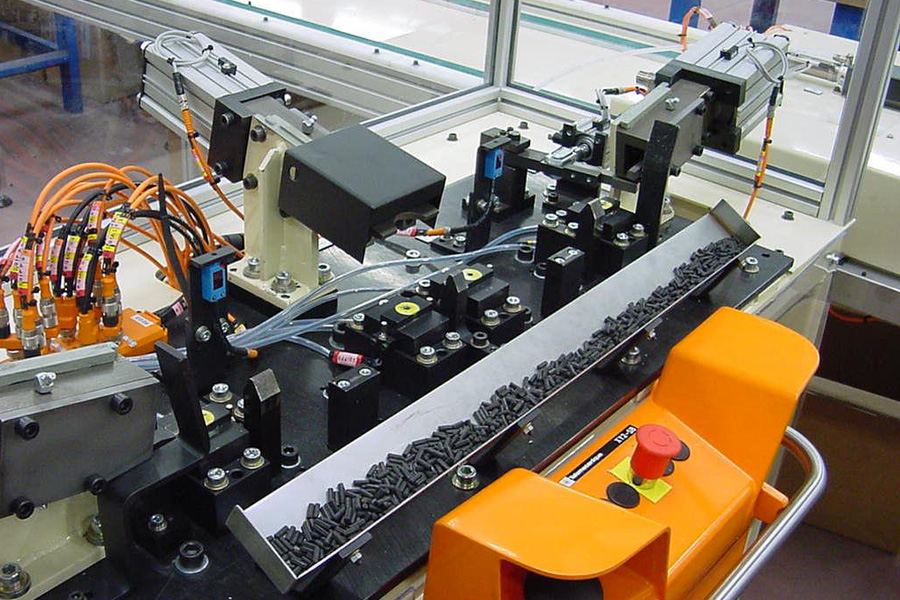

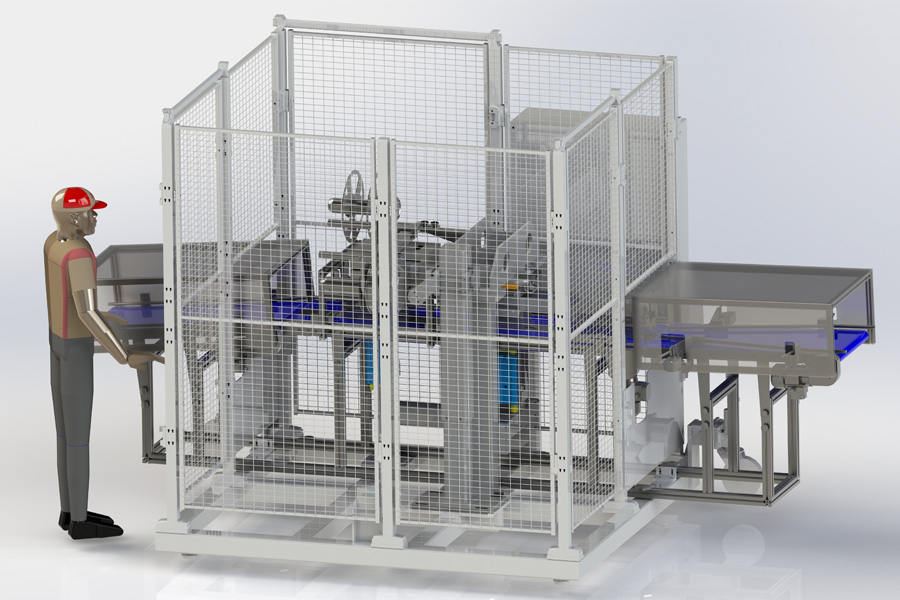

Assembly

ATI Solutions has also expanded its areas of work to include assembly. We make automated and robotic assembly equipment. The technologies used by ATI Solutions are: Crimping, riveting, clipping, heading, screwing, gluing, and extrusion.

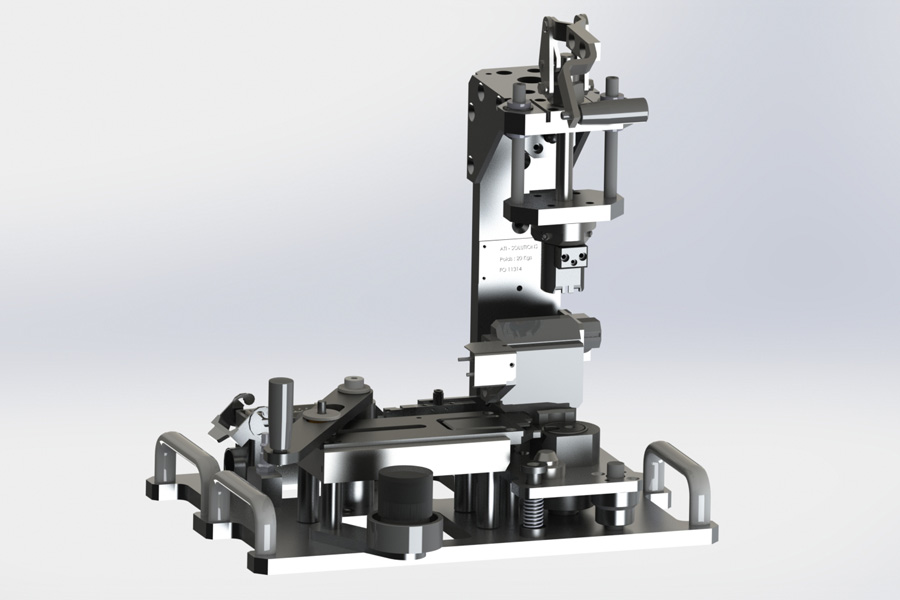

Machining

ATI Solutions studies your needs and offers you solutions that meet your fabrication criteria. We fabricate equipment that uses the following processes: Grinding, sanding, milling, drilling, and punching.

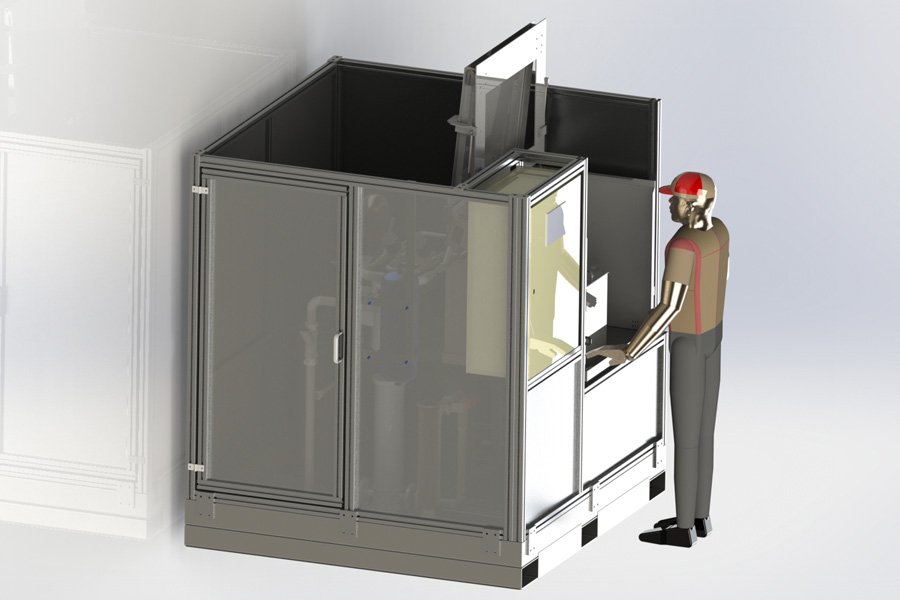

Cleaning and marking

In order to meet manufacturing and identification criteria (production tracking and packaging), the industrial processes include cleaning and marking equipment. For any specific need, ATI Solutions designs and produces special equipment.